2024 China API Tiêu chuẩn Cổ áo và giày cho khoan giếng dầu

Thông số kỹ thuật sản phẩm

| Thuộc tính | Giá trị |

| Ứng dụng | Mỏ dầu |

| Tiêu chuẩn | API 5 CT |

| Vật liệu | Nhôm, thép |

| Các thành phần cốt lõi | Tàu áp lực, giày phao, cổ áo phao, lò xo, pít tông Sealtop |

| Kích thước (L*W*H) | 100-200mm |

| Cân nặng | 20 kg |

| Bảo hành | 1 năm |

| Tình trạng | Mới |

Các tính năng chính

- Khả năng chống mài mòn cao cho độ bền kéo dài

- Đáp ứng các tiêu chuẩn API 5 CT cho thiết bị khoan mỏ dầu

- Bao gồm báo cáo kiểm tra máy móc và kiểm tra máy móc gửi video

- Có sẵn với hỗ trợ kỹ thuật video sau khi bảo hành

- Có sẵn nhiều tùy chọn kích thước (xem thông số kỹ thuật)

Hồ sơ công ty

Chúng tôi (SWS) là một công ty chuyên nghiệp tham gia vào việc phát triển, sản xuất, bán hàng và dịch vụ các công cụ dầu mỏ. Sử dụng công nghệ sản xuất công cụ hạ cấp nâng cao từ Mỹ và Canada, chúng tôi cung cấp các phụ kiện vỏ vượt quá tiêu chuẩn chất lượng ngành để đáp ứng nhu cầu công cụ xi măng đầy thách thức của các mỏ dầu trên toàn thế giới.

Cơ sở sản xuất 78.000 m2 của chúng tôi có các thiết bị gia công, chế tạo và chế biến CNC hiện đại, cùng với các cơ sở kiểm tra và kiểm tra toàn diện.

Sản phẩm chính

Dòng sản phẩm của chúng tôi bao gồm cổ áo và giày, vòng cổ sân khấu, móc treo, đóng gói, phích cắm xi măng, đầu xi măng, trung tâm, vỏ và ống, khớp chó và khớp nối.

Chứng nhận

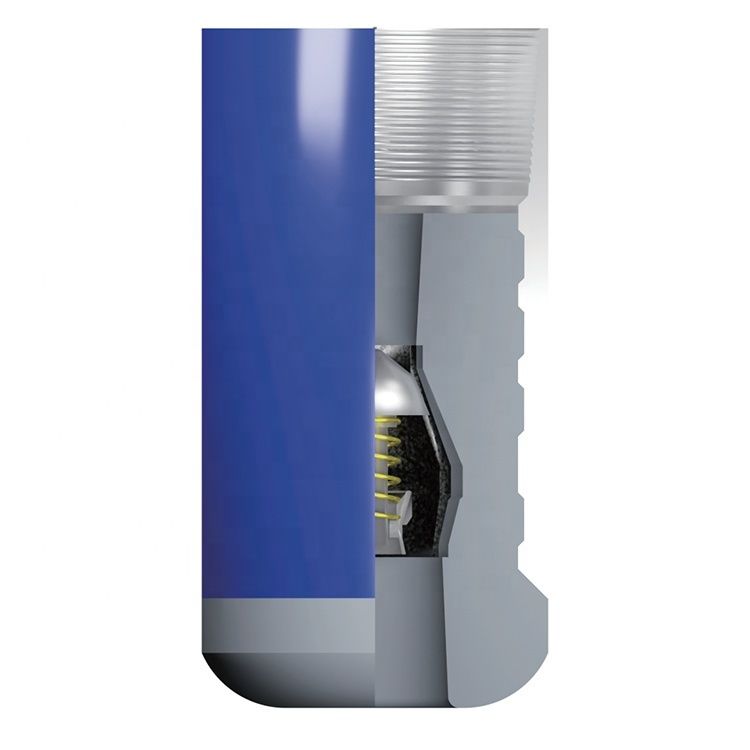

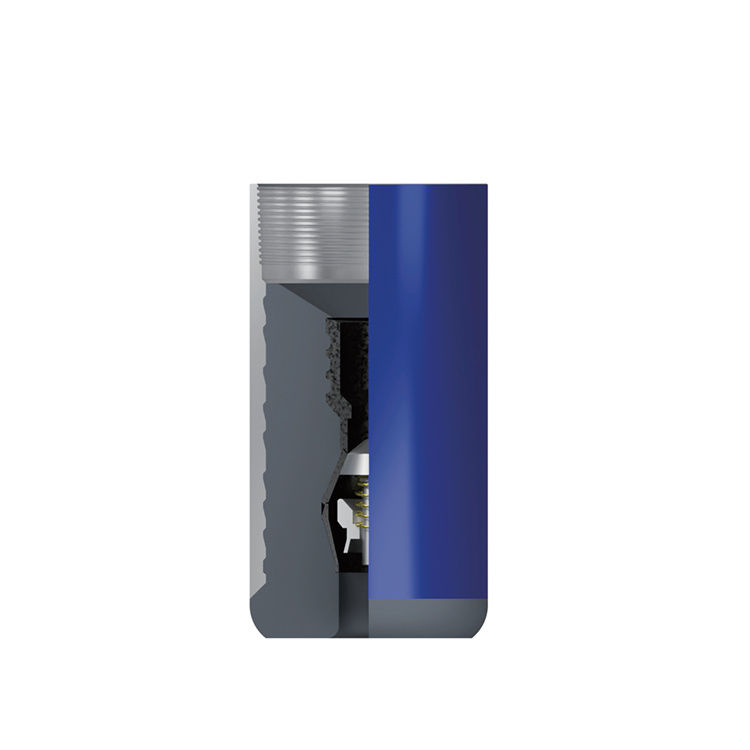

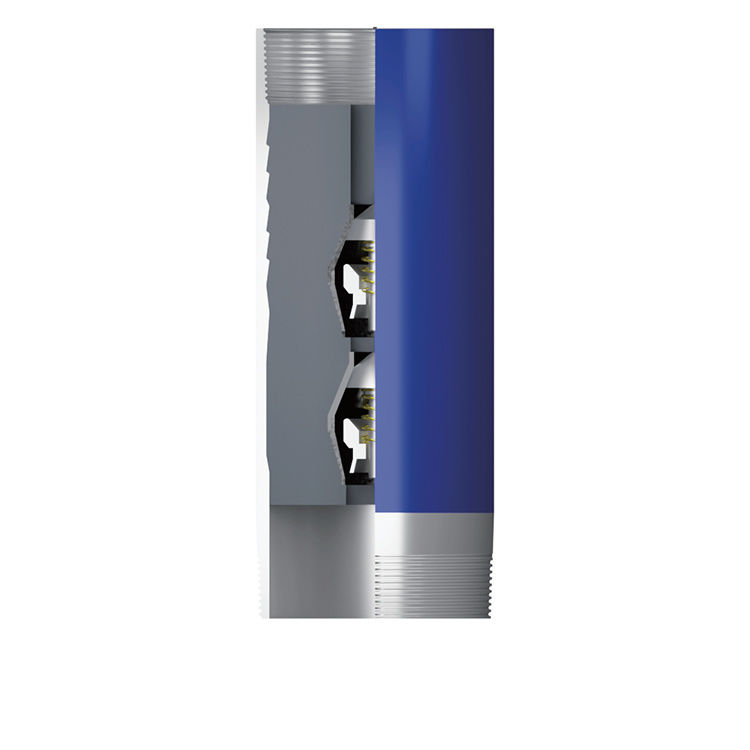

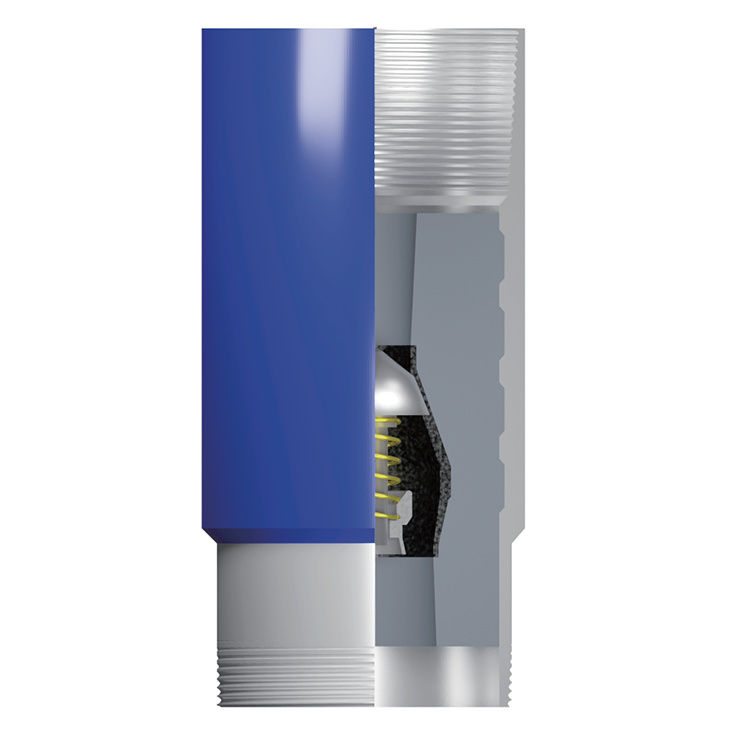

Mô tả sản phẩm

Thiết bị nổi đóng vai trò là xương sống của thiết bị vỏ được sử dụng trong các hoạt động xi măng chính. Nó hướng dẫn vỏ đến tổng độ sâu và ngăn ngừa bùn bị ô nhiễm xâm nhập vào vỏ. Ngoài ra, nó cung cấp một điểm hạ cánh cho phích cắm gạt nước, củng cố đầu dưới của chuỗi vỏ và đảm bảo dịch chuyển bùn xi măng chính xác.

Thông số kỹ thuật

- Van lưu lượng HI làm giảm xói mòn chất lỏng và giảm thiểu áp suất giảm

- Có sẵn hai kích cỡ: 70mm và 90mm

- Vật liệu nhựa tổng hợp có thể khoan PDC cho các thành phần van

- Con dấu tiêu chuẩn được đánh giá là 150 ° C với con dấu 204 ° C tùy chọn

- Cơ thể van được đúc bằng phenolic sợi (70MPa và con dấu 204 ° C)

- Lò xo làm từ vật liệu C510 bằng đồng phốt pho (lực phục hồi cao và có thể khoan)

- Pít tông được đúc bằng HNBR (con dấu 70MPa và 204 ° C)

Hình ảnh sản phẩm

Thông số kỹ thuật chi tiết

| Tên | Kích thước (trong) | BORE OD (IN) | BORE ID (IN) | Tham số Min Bore (IN) | Loại chủ đề | lb (in²) |

| Cổ áo phao | 5 1/2 " | 6 " | 4 3/4 " | 2 " | 5 1/2 "LCSG | 4351 |

| 7 " | 7 5/8 " | 6 1/4 " | 2 3/8 " | 7 "LCSG | 3626 |

| 9 5/8 " | 10 5/8 " | 8 5/8 " | 2 3/8 " | 9 5/8 "LCSG | 3626 |

| 13 3/8 " | 14 3/8 " | 12 3/8 " | 2 3/8 " | 13 3/8 "LCSG | 3626 |

| Giày nổi | 5 1/2 " | 6 " | 4 3/4 " | 2 " | 5 1/2 "LCSG | 4351 |

| 7 " | 7 5/8 " | 6 1/4 " | 2 3/8 " | 7 "LCSG | 3626 |

| 9 5/8 " | 10 5/8 " | 8 5/8 " | 2 3/8 " | 9 5/8 "LCSG | 3626 |

| 13 3/8 " | 14 3/8 " | 12 3/8 " | 2 3/8 " | 13 3/8 "LCSG | 3626 |

Cơ sở sản xuất

Thiết bị sản xuất

Triển lãm sản phẩm

Bao bì sản phẩm

Câu hỏi thường gặp

Q1: Khi nào tôi có thể nhận được giá?

Trả lời: Chúng tôi thường cung cấp báo giá trong vòng 24 giờ sau khi nhận được yêu cầu của bạn. Đối với các yêu cầu khẩn cấp, vui lòng cho biết điều này trong email của bạn để xử lý ưu tiên.

Q2: Tôi có thể có giá sản phẩm của bạn không?

A: Hoàn toàn. Vui lòng gửi cho chúng tôi yêu cầu của bạn qua email và bạn sẽ nhận được phản hồi của chúng tôi trong vòng 24 giờ.

Câu 3: Tôi có thể nhận được giá thấp hơn nếu tôi đặt hàng số lượng lớn không?

A: Có, chúng tôi cung cấp giảm giá khối lượng cho các đơn đặt hàng số lượng lớn hơn.

Q4: Bạn có kiểm tra các sản phẩm hoàn chỉnh không?

Trả lời: Có, bộ phận QC của chúng tôi tiến hành kiểm tra kỹ lưỡng ở mỗi giai đoạn sản xuất và sau khi hoàn thành trước khi vận chuyển.

Câu 5: Còn thời gian dẫn đầu để sản xuất hàng loạt thì sao?

A: Thời gian dẫn thay đổi tùy thuộc vào số lượng đặt hàng và nhu cầu theo mùa. Chúng tôi sẽ cung cấp các mốc thời gian cụ thể khi chúng tôi nhận được chi tiết đơn đặt hàng của bạn.